A bulk handling port had a loose material handling system constructed to feed biomass to the power generation industry. It was a new process to them and handled a different type of material.

There is pressure to keep the plant in operation as it costs their client for delays which in turn result in financial penalties, but the maintenance team are used to a less dusty and less hazardous material so fault-finding is basic and relies on quick fixes.

This is their story:

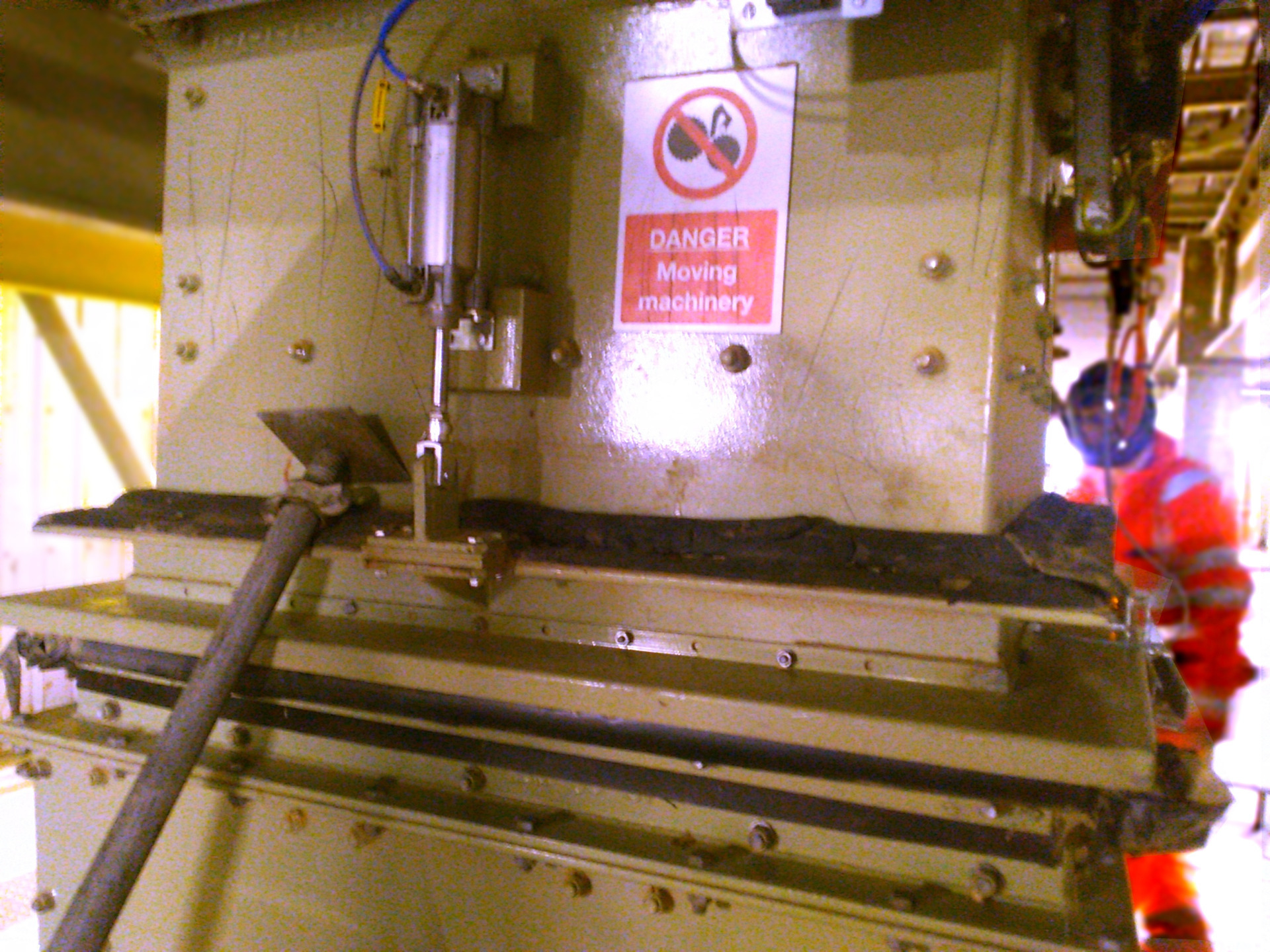

“We had a new facility installed, which transfers bulk materials into large silos from cargo ships. The materials are carried along a series of belt conveyors, but because they change direction and height, there’s quite a bit of dust around these points, and there’s the risk of explosion around the conveyors, and risk to personnel.

“Because of the health risk while transferring, when the material is discharged into the silos, our operations personnel aren’t in the area when this happens, and there’s been a substantial discharge within the distribution building. This needs to be cleaned up regularly to reduce the explosion risk, and interrupts the transfer of material from the ships, and that then delays their return, and also costs us in labour, extra berthing charges and loss of material.

“Our maintenance team have looked at it, and think the problem is the seal is not closing completely. So they’ve added an extra pad to close the gap. But this isn’t really working. In addition they report that the carriage has over run, and damaged the building housing.

“This needs to be solved, and quickly. Our team aren’t yet fully conversant with the inner workings of the plant and we don’t have the expertise in-house to hold up production while they learn.

“As MAT had shown a lot of competence during the design stages, we called them in to help us resolve the issue.“

“The Client had unfortunately not had a great deal of training in use of their new plant. Because it had been built in three stages, and put to use immediately after the first stage of completion, full training hadn’t been easy to achieve and it illustrates one of the reasons why operator engagement during design and construction and proper training is so vital.

“MAT had previously worked on this plant design so we were in a perfect position to be able to quickly analyse the causes of the problems.

“The window of opportunity to examine at close quarters what was happening was very small, so before even setting foot on site, we knew what information to gather so we could maximise the limited period when the client was prepared to suspend operations.

“We looked at how the plant was intended to operate and compared with how it was being used by the operators and identified some differences in procedures and several installation problems which could all be contributing to the spillage, including gaps, misalignment, maintenance omission and a design change. Whilst on site, we were also asked to advise on the overloading of a dust filter, which we were happy to include.

Our report included details of the likely causes and suggested solutions that the client would have capability to deal with internally with the least additional disruption.

Although MAT had the advantage of previously working on this project, we know that problems reported don’t necessarily provide the whole story, and it requires a forensic and non-critical approach to be able to tease the information out to gain a full understanding of the causes and reasons. This results in an active ownership of the solution by all personnel and confidence by plant management that their problem can be removed.